Sensors

News

Datalogic has acquired MD Micro Detectors operating in the design, production and sale of industrial sensors. The acquisition will allow the Group Datalogic to strengthen its Italian and global presence in the industrial automation market, through the integration of sensors, safety devices and machine safety product portfolio.

The highly innovative content of M.D. Micro Detectors combined with Datalogic’s product portfolio and distribution network represents a growth project that aims at creating the main Italian hub for sensors in the industrial automation sector.

Datalogic and M.D. customers can continue to contact their commercial references, with the advantage of having a greater choice of products and solutions for the most varied industrial automation applications, thanks to the widest range of sensors, safety devices and machine vision.

Sensors

Sensors are indispensable for the industrial automation of plants and machinery in a wide range of industries and applications, from manufacturing to logistics.

Manufacturing industry applications include factory automation of automotive and electronics plants; food & beverage, pharmaceutical, chemical goods processing and packaging machines; up to almost any machinery used in woodworking, metalworking, textile, ceramic, glass, stones, paper, etc.

Logistics applications are diffused in automated material handling, conveyors, storage and retrieval systems, automated warehouses, transportation systems, and distribution centers.

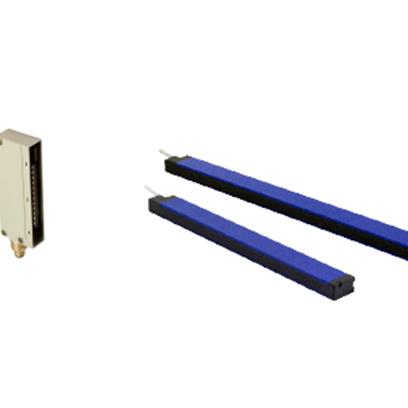

Photoelectric sensors are devices that use the emission and reception of light to detect the presence of objects or their parts, inspect their integrity or correct assembly, measure their dimensions, distance or correct positioning.

In this regard, they can be distinguished in a great variety of sensors: thru-beam emitters and receivers, or retro-reflective units; diffuse, fix focus and background suppression; fiber optics amplifiers; fork sensors; contrast, color, and luminescence sensors; distance or dimensional sensors; vision sensors.

Datalogic's smart photoelectric sensors, together with complementary products like inductive proximity, ultrasonic sensor, optical encoders, and accessories allow companies to enhance their manufacturing and logistics processes.

Sensors Common Applications

Whether you need to implement detection, inspection, or measuring applications for your production or distribution of any type of goods, or you want to improve your processes according to the new paradigms of digital manufacturing, sensors are an essential element of your automation. Applications are innumerable, constantly evolving, and cannot be summarized in a few lines. However, the following examples can give an idea of the unlimited potential of sensors:

- Small parts can be detected at high speed, even in the presence of other nearby objects or reflective surfaces. This is possible through background suppression photoelectric sensors, also with laser or fiber optics, or even inductive proximity in case of metal parts at short distance.

-

Clear objects, such as PET bottles, glass vials, or even thin plastic packaging films, can be reliably detected with polarized retro-reflective photoelectric sensors with coaxial emission.

-

Print registration marks, essential for any processing or packaging machine, are detected at the highest speeds and resolution regardless of the colors. This is due to the contrast photoelectric sensors, also in case of invisible luminescent marks using UV light emission.

-

Labels of any color, size, and placed on any type of reel, including clear-on-clear, are detected by fork sensors, with photoelectric or ultrasonic sensors, depending on the application.

-

Distance and positioning of objects can be measured with millimeter precision, even with ranges of several meters, through laser photoelectric sensors time of flight (TOF) measurement, or even ultrasonic sensors for clear objects and optical encoders for linear measurement.

- Dimensions are measured through photoelectric sensors with multi-beam light arrays, formed by emitting and receiving units, dynamically sending the data and reconstructing the profile of the measured objects.

-

Quality can be inspected in any production phase: from loading to assembling mechanical or electronic parts, from processing to packaging food or pharmaceutical products, from filling to closing bottles, from printing to apply labels. Smart vision sensors which acquire and distinguish "good" and "no good" images make inspection possible.

Sensors Common Benefits

Introducing sensors into your automation, instead of standard sensors, means adapting production and logistics processes to the latest digital transformation requirements.

Main common benefits are improved productivity and efficiency, more flexibility and traceability, increased profitability in terms of total cost of ownership and time savings, thanks to the following advantages:

- Experience - Datalogic is among the pioneers and major manufacturers of photoelectric sensors, among the few to have proprietary ASIC technologies. For the user this is a guarantee of proven product knowledge, reliability, and best sensor solution.

-

Wide Range in terms of product lines, form factors from miniature and compact to larger sensors, light emission types from LED to Laser, detection, measurement and inspection functions, resolution and distance range, interfaces, accessories, etc. The user has always the best ratio between performance and cost, paying just what is necessary.

-

Advanced features like special algorithms for clear or highly reflective object detection; proprietary ASIC with embedded IO-Link interface; TOF measurement patents; machine learning assisted setting smart vision sensor technology. All this is not just innovation but represents benefits. Indeed, user can optimize the process, doing it better, faster, more reliably, saving time or components.

-

Custom product and special version, based on core photoelectric sensor technology, represent another way in which Datalogic wants to be closer to customers and solve their most specific needs.