What is Machine Vision

It can recognize the content of the images.

Machine vision uses cameras to capture images from the environment.

Then it leverages on a mix of hardware and software to elaborate the information.

Two of the most useful macro-applications of machine vision are automatic target recognition and industrial inspection (i.e., machine vision used to analyze the goodness of a component on an assembly line).

More in detail, some specific industrial machine vision applications could be:

- Object recognition

In robotics, machine vision could help in identifying the presence of obstacles.

Machine vision systems also determine the position of objects, such as the proper placement of labels on packages.

- Pattern recognition

In wood processing, industrial vision systems can be used to identify the presence of any strange patterns in the material to signal eventual defects.

- Optical character recognition

OCR enables a computer to extract printed or handwritten text from images and to understand the content and the meaning.

In labeling, it is possible to automatically control the content and its correctness.

- Materials inspection

Machine vision capabilities in materials inspection systems ensure quality control.

Machine vision checks for flaws, defects, and contaminants in a range of materials and products.

- Electronic component analysis

Machine vision is used in the manufacturing of circuit boards for tasks such as solder paste inspection and component placement.

- Items counting

This capability is used to count the items such as pills in a packet or bottles in a case.

Machine vision, paired with AI and deep learning, expands the role of robots in performing production-line tasks (i.e. picking) and performing a manufacturing line scan.

This combination of technologies also enables robotics to operate in retail contexts, like in stores or restaurants.

Machine vision technology enables automation and supports the collaboration between robots and humans.

Machine Vision systems

- Lighting

The right light is essential to grant

an effective capture of the surrounding scene and make it visible.

It is often

necessary to implement some filters to adjust the right wavelength to be

processed

- Lenses

They have the role of capturing the

images and sending them to the sensor inside the camera, together with light. Different

types of lenses exist, with diverse mechanical and optical features (i.e.,

C-Mount, microlenses)

- Capture board and sensor

They process images

coming from the camera; then convert them in a digital extension.

The

conversion of light into electrical signals is done thanks to one of the

following technologies: complementary metal-oxide semiconductor or

charge-coupled device

- Software

A software with different tools,

enabling the industrial vision system to accomplish all the different machine

vision functions

- Processor

The processor has the aim of running

software and the related algorithms able to process the image and extract the

required information

- Communication/connectivity

Systems enabling the

machine vision cameras and processing system to communicate with other elements

of the bigger system (using either input/output signal or a serial connection).

Two main types of machine vision cameras can be implemented:

- Area scan, based on rectangular sensor, able to

catch an entire picture with number of pixels given by height X width

- Line scan, where the sensor passes in linear

motion over the target object when taking a picture pixel for pixel

The main specifications in any vision system are sensitivity

and resolution.

The sensitivity refers to the ability of perceiving signals

with low light and to detect weak impulses at invisible wavelengths.

Machine Vision vs Computer Vision

Machine vision is often associated with industrial applications of a computer's ability to see.

The term computer vision is often used to describe any technologies where a computer is tasked with:

- digitizing images captured by computer vision cameras

- processing the data, it contains

- acting

Another distinction that is sometimes made is in processing power -- that is, the difference between a machine and a computer.

A machine vision system typically has less processing power.

It performs practical tasks at a high speed.

Computer vision systems collect as much data as possible about objects or scenes and aim to fully understand them. It could be performed also without cameras.

Why should you use Machine Vision in industrial processes?

- Effective tool granting consistent and accurate quality inspection.

- The human intervention in quality control could lead to subjective judgements

- Reduction of labor costs, due to the employment of automated solutions instead of humans

- Reduction of scrap, due to a faster defects’ detection with the possibility of rework them or to throw them away

- Remote monitoring, with the possibility of performing inspection far from the production line.

- Safety reasons: remove humans from dangerous processes

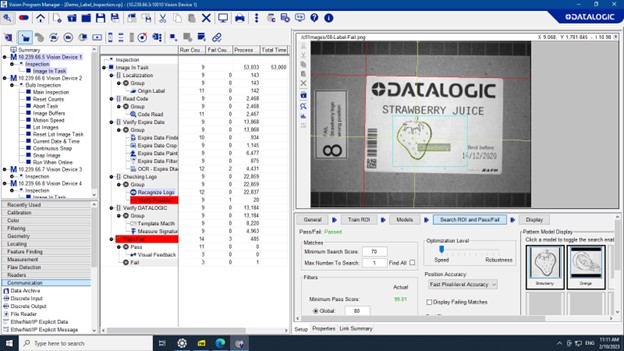

Impact suite: Datasensing Machine Vision software

It is possible to create your own vision program and select the vision device to be used.

The software shows the same behavior on different hardware devices.

Some of the most powerful tools of IMPACT include:

- Advanced OCR

- Blob

- Pattern find

- Edge detection

- Color analysis

- Image filtering

- Blue Eye

In particular, the Blue Eye tool has been included into the new release of IMPACT 13.2.

It shows comparable performances with pattern find, but with multiple pattern locator and innovative methods to compute template affinity or scoring.

The SCM (Smart Camera Monitor), enables the remote control of camera inspection through any device connected to the web.

IMPACT configuration files are fully portable from one Datasensing hardware device to the other.

The IMPACT suite is based on three main modules: VPM, CPM and SDK. The Vision Program Manager represents the front end to define the vision inspection characteristics.

- Multi-Camera Connection Support

- Intuitive Drag & Drop Programming

- Logic Tools allowing Explicit Control

- Tree View provides easy to follow Tool Programming & Debugging

- Tool Setups for easy Configuring, and Properties for greater Access

- More than 100 Standard Tools

- More than 20 Logic Tools

- Possibility to code, but without the necessity to do it

- Built-in Display Panel provides Configurable Operator Interface

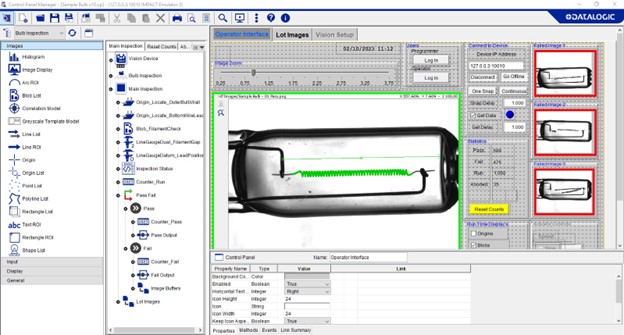

The Control Panel Manager is a software aimed to design HMI direct connected to the Vision Device.

Its main features are:

- Drag & Drop, Point & Click Programming for Customizable Operator Interfaces

- Support of Multiple Camera Connections

- Allows for Bi-Directional, Runtime Control of all IMPACT Cameras

- Supports 5 levels of Password Protection

- More than 45 Standard Controls

Software Development Kit (SDK)

So, they have a single control point for the whole manufacturing line.

P2x: the powerful smart camera for your machine vision applications

The P2x Series is an industrial smart camera that offers exceptional performance and flexibility in a compact, fully integrated form factor.Supporting over 100 inspection tools in the IMPACT software suite, the P2x Series allows you to tackle even the most complex machine vision application requirements.

Customers can choose among several types of micro-video lenses and C-mount lenses: both lenses’ formats are supported by the P2x series.

The vision smart cameras P2x presents embedded cover with illuminator.

It is also possible to select other covers, illuminators, or filters from a wide variety of products present in the range.

This enhances the right degree of product maintainability.

The reduction of time devoted to product setting, orientation, maintenance, and adjustment leads to higher production efficiency.

Reduction of machinery downtimes lead to higher OEE (Overall Equipment Effectiveness) and to a cost reduction for the plants and factories which would adopt this machine vision solution.

Machine Vision Applications

Defect and anomalies detection

Machine vision is mainly used in quality control, with the double aim of increasing the product quality/accuracy and to reduce costs related to poor product quality (due for instance to scraps or defects product returns).Machine vision can be used to detect defects and anomalies on manufactured products, like the presence of scratches or cracks on the surface.

Furthermore, machine vision can be used also to detect the right product surface color.

Vision systems can be implemented also to detect the presence/absence of certain products inside boxes/packages or to count them. This is made to assure that the right number of pieces has been packed and is going to be delivered.

In some critical applications, like in pharmaceutical manufacturing lines, machine vision can be used to verify the package integrity (i.e. check the integrity of medicine vials).

In some other applications, the machine vision systems are used to verify the correct orientation of an object inside the packaging.

A particular example is represented by the electronics industry.

Machine vision inspection is used on electronic components and printed circuit boards (PCBs) to identify defects.

An advantage is its ability to detect defects that are difficult or impossible to identify using human inspection. It is easy to use, set up, and maintain.

Machine vision inspection has become a vital part of the vehicle manufacturing process. Basically, any car part requiring visual inspection, including defect detection, completeness check, product sorting, OCR or OCV on components mark.

Size measurement

Vision inspection can measure the distances between different points and, as consequence, to assess the correct shapes on the product surface.

Machine Vision in robotics

It can perform these logistics activities with higher speed and accuracy with respect to human operators.

Furthermore, the usage of machine vision allows to avoid excessive efforts for humans and/or the access to dangerous areas.

Character reading applications

In manufacturing, character reading can be used to check the contents of product labels, to verify their correctness or to check if a product has already expired or not.

These applications can support the product traceability over that product quality.

PEKAT VISION deep learning platform

The deep learning platform offers an intuitive and user-friendly software environment.

No programming knowledge is required as it already contains all the necessary modules for industrial visual inspection.

It is compatible with many hardware brands, Windows® and Linux® operating systems and runs on embedded devices.

This is a machine vision software based on deep learning technology.

Through the support of neural networks, it can solve also the most complicated machine vision applications where it is not so easy to address the solution through traditional vision software.

Plastic and rubber

These defects may include various types of stains, burrs, inclusions, voids, or cracks.

The platform consists of several modules able to identify such defects, detect missing parts and read an verify any sign and symbol.

It can even detect defects, such as stains, micro voids, cracks, or inclusions, that are difficult to identify manually or by a rule-based vision system, as they are too small or hard to notice.

Furthermore, for cases when the form of the defect is difficult to anticipate, PEKAT VISION offers the Anomaly Detector module, requiring only defect-free images for training.

Metal fabrication

Furthermore, manual inspection is time consuming, and the results are often inconsistent.

The platform has already been successfully applied in several activities: from input material inspection, up to assembly and packaging verification.

Its reliable visual inspection based on advanced deep-learning algorithms and neural network easily finds anomalies and detect and classifies defects, including cracks, scratches, sand inclusions and blowholes, corrosion defects, stains, and many other defects or imperfections.

Textile

It is well suited for inspection of textile and other woven and knitted fabrics, non-woven fabrics, leather, plastic or rubber foils, filter fillings, paper, surgical sheets and many other materials.

Using the Anomaly Detector module, defect of previously unknown shape, pattern, and size are identified. Furthermore, the results are not diminished by irregularities on the fabric as it learns and recognizes the pattern, something that may be difficult with manual inspection.

For clarity, the defect is always highlighted with a heat map.

Pharma and cosmetics

It ensures product quality, including packaging and seal integrity, sterility, and appropriate labeling, helping to ensure regulatory compliance.

The platform offers a selection of tools able to tackle many challenges in the pharmaceutical manufacturing, including completeness verification and packaging integrity inspection, defect and contaminant detection, label reading and verification and much more.

Wood, flooring, furniture

Food and Beverage

The deep learning platform uses proprietary deep-learning algorithms and neural network to accurately analyze vast amount of visual data in real time, detecting defects and anomalies that may be missed by conventional methods. Its modules can identify solid contaminants, check packaging integrity and completeness, verify that correct labels are in place, read best by/ sell by dates and much more.